Why Compass?

CAPABILITIES

Comprised of the world’s best-in-class dive brands, our COMPASS Division delivers elite gear by leveraging Huish Outdoors’ persistent R&D, industrial capacities and logistical know-how.

Our products are built on generations of dive expertise. We have been designing, engineering and manufacturing professional equipment for over 50 years, and the combined experience of our brands is unsurpassed.

We have a strong international footprint. Across multiple design centers in Utah, California, British Columbia and Europe, we tap the best minds in dive to conceive, engineer, build, refine and test the most reliable gear in the world.

All of our research and development stems from the customer. From commercial enterprises, to rescue missions, to military units, we adapt to meet the needs of your operation.

Drysuit Customization

Whatever the mission, BARE has your team’s back. Elite engineering, top construction and industry-leading know-how come together in all of our immersion wear—all dialed to your exact specifications.

In fact, we offer 95 drysuit options to meet the demands of your team. That means custom solutions for the most extreme conditions and environments. From customized waterproof pockets, to double-safety exhaust valves for polluted waters, to non-magnetic drysuits for mine-clearance and combat, we’ve thought of all the details, so you can focus on executing your objective.

Materials

We design and manufacture our products for extreme, professional use.

That’s why we only use field-proven ballistic nylon and ultra-durable fabrics that have been tested for puncture protection, tensile strength and resistance to UV, Salt, Chlorine and other corrosive chemicals.

Our regulators and instruments are second to none. The COMPASS Division only utilizes materials that will meet and exceed the US Navy‘s demanding requirements.

PARTNERS

The COMPASS Division partners with the top commercial, public safety, armed forces, and search and recovery professionals in the world. We are proud to support their missions, and we are ready to support yours.

Since the 1960s, our brands have serviced and supported military professionals, first responders and commercial divers. And today we are deployed with elite teams and professional users around the world.

Some of the notable global partners we equip include:

- US Department of Defense

- US Special Forces Combat Divers

- US Navy

- US Coast Guard

- Australian Defense Force (ADF)

- Ministry of Defense

- International Navy Forces

- First Responders

- Police and Fire

- Offshore Oil and Gas Customers

PRODUCTION

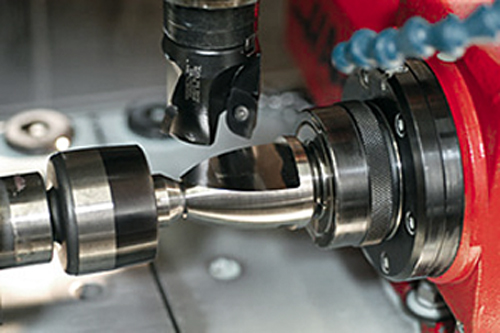

In order to meet the highest standards possible for our life-support products, our engineers utilize CAD/CAM for product design and CMM digital mapping for quality control. Huish Outdoors’ in-house CNC machining facility allows for full control of prototyping and production.

Our commitment to performance is realized through testing. Our diving regulators are EN250 certified and meet US Navy performance standards. This ensures the lowest work of breathing (WOB) possible through the use of an in-house ANSTI breathing machine. Every regulator produced by Huish Outdoors is ANSTI tested before leaving the factory.

Our collection of EN1809-certified buoyancy compensators deliver guaranteed performance. The Salt Lake City, Utah factory produces Berry Compliant buoyancy products that meet the ANU standard under #1.0.3.

We also design, develop, test and manufacture our immersion and drysuit exposure wear within Huish Outdoors’ production facilities.

Berry Compliant

Sure, “Made in America” is a good start. But a better metric for supporting American workers is whether a company uses American-made materials. And that’s what the Berry Amendment is all about.

Berry compliance takes a company’s commitment to American manufacturing a level deeper, because something can be made in America, from outsourced goods. Not only does Zeagle produce equipment on US soil—we use materials made in the US for many of our products. From end to end, we’re supporting hard-working Americans all across the supply chain.